Americans have been aware for decades that their nation is in the midst of serious industrial decline. This decline, represented by the loss of some 7.5 million jobs between 1980 and 2017, has affected whites, African Americans, and particularly men, more than any other group. The Bureau of Labor Statistics has found that for every 10 percentage point drop in regional manufacturing share there is an accompanying 3.7% drop in male employment. While women suffer a 2.7% drop in employment and local governments suffered massive declines in available tax-dollars to provision services.

Financialization, free trade, corporate profit-chasing, mass immigration, and numerous other factors led to the decline of American manufacturing. But, while academics bicker about which of these factors is the most significant in the decline, Americans continue to hurt, families continue to dissolve, and Americans continue to become poorer. Due to this decline an entire region of the United States is now known as the “Rust Belt” and its population is in a near terminal poverty driven spiral. We can use the state of Michigan as an example.

In the 1960s, at the height of American economic might, Michigan possessed the 6th largest economy in the United States. Ahead of states like Florida and Texas, and larger than most Western European nations at the time. Michiganders enjoyed a per capita income some 20 points (and thousands of dollars) higher than the national average. Today, after decades of de-industrialization, financialization, free-trade practices, and cheap labor (to name but a few issues), Michigan is only the 14th largest economy in the nation. A ranking which continues to decline with each passing decade.

The industrial Midwest and modern-day Rust Belt: Michigan, Ohio, Pennsylvania, Indiana, and parts of other states once formed one of the greatest concentrations of familial wealth and income in the world. Prosperity was abundant for the average resident of these very states.

Today Michigan ranks 17th in the nation for poverty, and 34th for personal income. Detroit, once the "Paris of the West," now more closely resembles a bombed out husk. Detroit is a city which was once the richest in the nation, and according to some economists the richest city in the world at its peak.

What is left of the manufacturing sector is an economic redoubt for only some Americanss. In 2021 the Manufacturing Institute reported that 79.5% of remaining manufacturing jobs are held by whites while 70.8% of manufacturing workers are male. The destruction of these traditional industries can be directly linked to the destruction of historic American communities and many of the ills which plague men today.

If American policymakers seek a truly revolutionary change in the standard of living for their citizens then they must take steps to revive the manufacturing sector. The Bureau of Economic Analysis shows that manufacturing, more than any other sector, contributes to prosperity. For every dollar a manufacturer spends into the economy a $1.48 in other services will be generated. By contrast the multiplier for a dollar of retail sector spending will only generate an additional 54 cents for the economy.

The Rhode Island manufacturers Association goes further, claiming that for every dollar their sector spends an additional $2.74 is generated for the American economy. While the University of Maryland claimed, as of 2014, that the multiplier for a dollar of manufacturing spending was $1.92 in wealth creation for the wider economy.

Policymakers must consider the following options if they seek to generate prosperity for Americans:

1. Local content requirements

The surest way to ensure that products purchased by Americans are produced by Americans is to ensure that those products have their component parts sourced in the United States.

During the 2015-2016 elections Americans were shown incredibly dishonest estimates by the media that manufacturing an iPhone in the United States may cause the price of the prized smartphone to skyrocket. Even today articles continue to come out promoting the idea that the iPhone could increase some $1,400 in cost were it to be made by American workers, but this is simply not the case.

The actual experts, not the media, at the MIT Technology Review put together a wonderful 2016 piece showing that if most of the inputs in the manufacturing and final assembly processes for the iPhone produced in the United States it would cost just an additional $100 for the American consumer to purchase an iPhone This is an incredibly modest price to pay, especially considering that the effect would be the reshoring some of the 1.6 million jobs which the production of Apple products has created abroad.

American policymakers must institute a 51% local content requirement for any goods which are related to: transportation, technology, energy (production & transmission), national security, food production, and other forms of critical infrastructure.

2. Provide financing for new firms

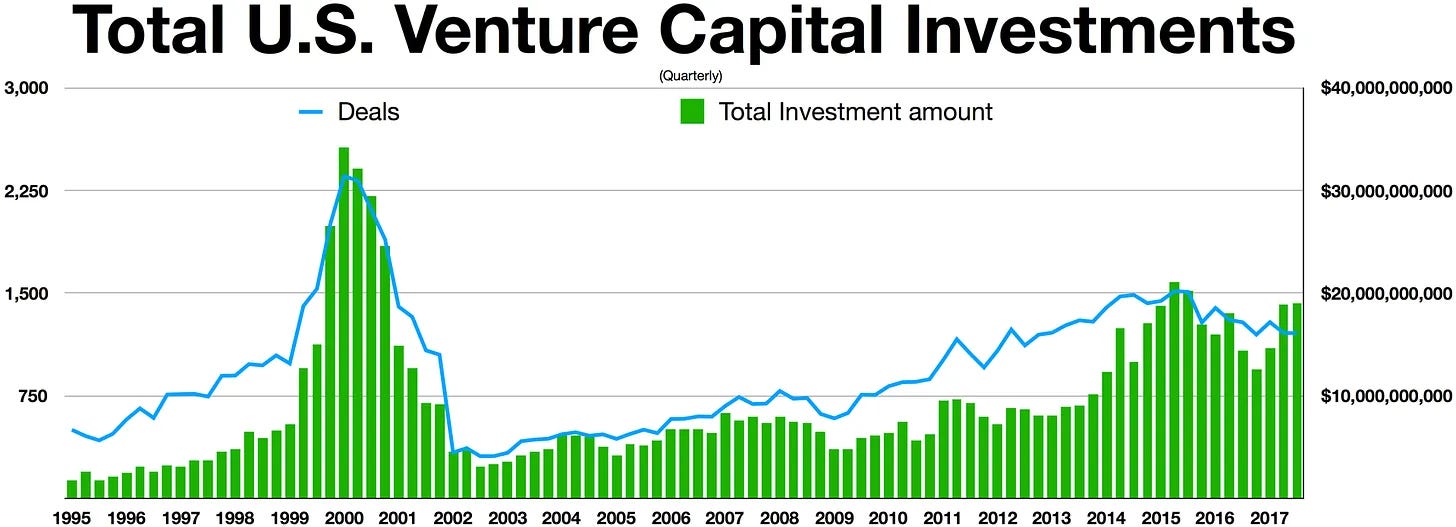

The American private sector is fantastic at allocating funding for new ventures which seek to turn ideas into viable products and services. Venture capital in particular invests 10s of billions annually in start-up firms, many of which grow out of the garages of America’s university students. Yet, these venture capitalists do not see the process through to the end.

A 2014 study by the Massachusetts Institute of Technology found that while venture capital is willing, even eager, to fund the initial stages of development those same VC firms are near universally unwilling to fund the scale-up of manufacturing capacity. This results in firms founded by innovative young Americans to look abroad to China, to Vietnam, to Brazil, to scale their manufacturing processes, because they cannot secure the necessary funding at home.

As a result the active industrial policies of other countries, which fill this critical funding gap to allow for manufacuturing at scale, undercut American manufacturing potential and result in Americans importing products they should otherwise be producing themselves.

American policymakers therefore must fill the gap by providing financing during the crucial scale-up phase. Japan provides direct subsidies to firms, while the United Kingdom has a development bank, owned by the state, which provides long-term financing so that firms can get to scale on the domestic market. In Germany private commercial banks still do the majority of lending to build manufacturing facilities, though relationships are often facilitated by state institutions.

American policymakers can and should try a variety of approaches, enabled by the nation’s Federal nature. Some states could found state owned investment vehicles, others could simply facilitate the meeting of private capital and new industrial firms, while other states may establish sovereign wealth funds to invest in scale-up phases. Solutions abound, and its time American policymakers begin taking them.

3. Get Creative - One County One Factory

American policymakers must also get creative by establishing promotional policies which drive local governments to push for industrialization. One country with an inspirational program is the African nation of Ghana, which founded a program known as One District One Factory (1D1F). Under 1D1F the local governments, the districts, of Ghana work in concert with local producers and the national government to facilitate the establishment of private enterprises which process Ghanaian inputs into higher-value products for both domestic consumption and export.

A perfect example of this process is the Fairafric chocolate factory, which is taking locally grown Ghanaian cocoa beans (70% of the global supply is grown in Africa) and turning them into finished chocolate products. This new factory has also resulted in new growth for other industries, such as companies which provide the wrappings for the chocolate. Previously just 1% of cocoa products were refined in Africa.

The United States should follow the Ghanaian example. American policymakers at the local, state and Federal level should establish a “one county one factory” (1C1F) initiative which seeks to promote and support the establishment of manufacturing and processing facilities in the United States.

A perfect example of the utility of the 1C1F approach would be in the American seafood sector.

American fishermen catch some of the cleanest and most high-quality seafood in the world, massive portions of which are then exported abroad. American fish is sent abroad to be processed by foreign companies and then either consumed by those populations or re-imported to the United States. These products also often return to American shores as a lower-quality type of fish.

A fish caught in Alaska often, therefore, takes a 9,000+ mile journey around the world before returning to the United States, and it may be of inferior quality upon return. This is ridiculous.

Instead of exporting 600 million pounds of quality American pollock abroad to be processed and then re-imported the United States should, at all levels of government, promote a One County One Factory policy which would see American products processed in the United States and sold on the American market, or exported as a finished (and therefore higher-value) product.

A similar process is also happening with American lumber exports. China imports a great portion of American lumber, only to then process the raw material and re-export it to the global market, undercutting a value-chain which Americans should be profiting from.

White Americans are still the majority in 81% of the nation’s 3,100 counties and therefore would benefit most from a One County One Factory policy initiative.

Some final points:

1. The Skills Gap

A key feature of the modern economy which is holding back the growth of industry in America is the manufacturing skills gap. This gap was created due to the massive offshoring of American jobs, and therefore expertise, which has taken place over the previous 40 years.

The United States needs to train new industrial employees, and some states have taken the initiative. A Wisconsin Department of Workforce Development grant helped a local company which suffered a near 100% turnover rate to establish a training center which has since reduced its turnover to just 15%.

The American state, unions, community colleges, and private enterprise must come together to establish a nation-wide network of training programs which give Americans the ability to train for the manufacturing jobs in their area and companies to tailor said programs to their needs.

2. Workforce Participation

Roughly 8.5 million prime age (25-54 year old) white men are currently unemployed, under-employed or not in the labour force. Research by the Institute for Family Studies shows that these men are not lazy, disinterested or otherwise “broken” by some personal fault. Rather, many are plagued by a childhood spent in the now all-too-common and deeply dysfunctional single-parent households which blanket the nation. Others are suffering from the same mental health crisis which is leading White men, who make up 70% of suicides in the United States, to kill themselves en masse each year.

Reindustrializing the United States would result in ample good paying jobs which would enable young men to once again attract mates, build families, and have a sense of value both in themselves and from their communities. The reindustrialization of America is the rebirth of American civic life.

Support our mission to take on more writers and contributors:

Zelle: whitepapersinstitute@protonmail.com

Buy us a coffee: https://www.buymeacoffee.com/wppi

Linktree: https://linktr.ee/wppi

Snail Mail: White Papers Policy, PO Box 192, Hancock, MD 21750

I think we should also look at a 'workshop' initiative to provide resources and facilities for small production projects and prototyping.

Also, every country ought to have a weapons manufacturing facility.